AGV Knowledge Series: Part 3 –AGV vs AMR

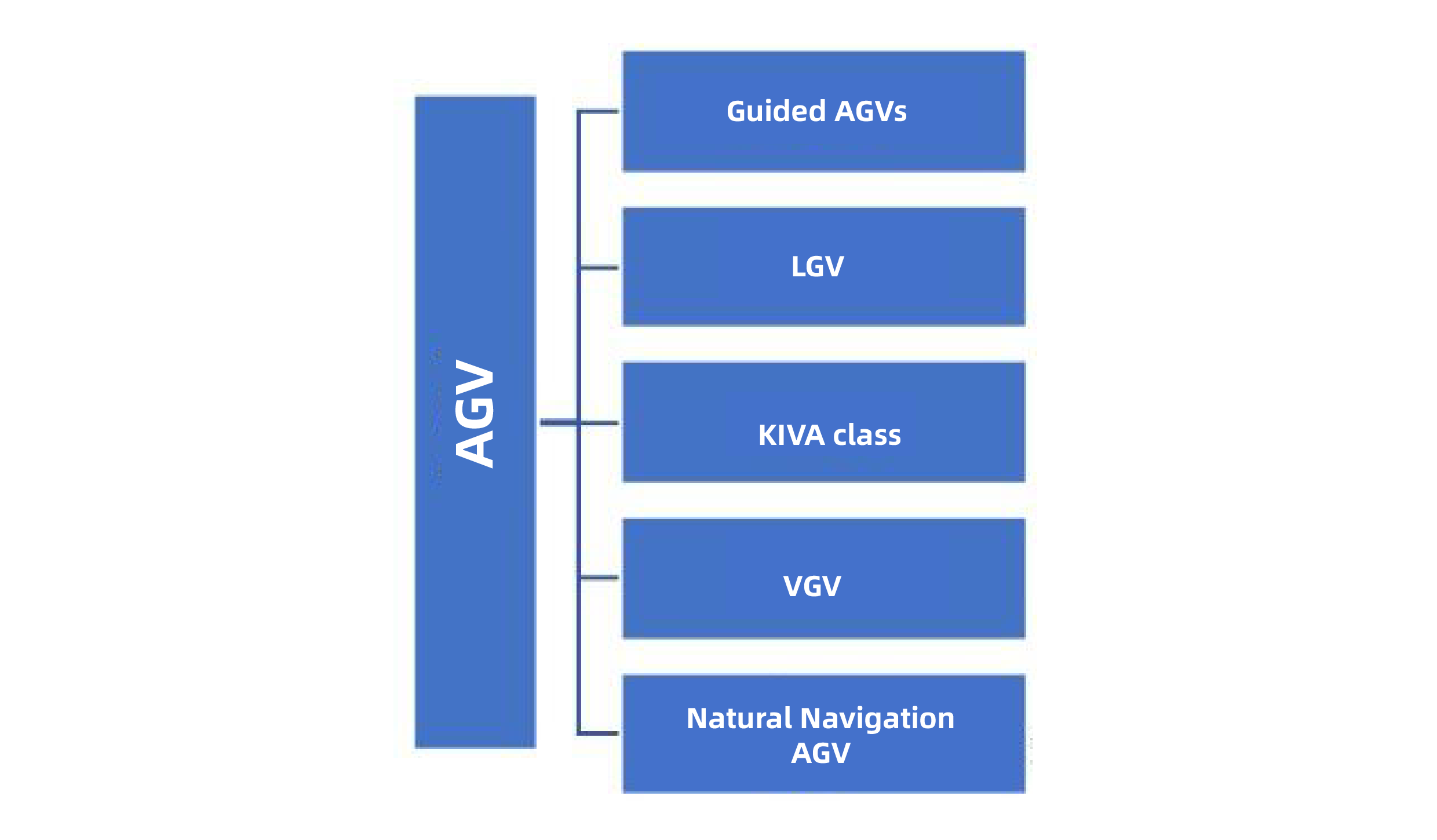

In the intelligent upgrading of manufacturing and logistics industries, Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs) have emerged as core technologies for automated material handling. However, they exhibit significant differences in navigation methods, cost structures, and environmental adaptability. AGVs ensure high precision through fixed routes, making them suitable for stable operational environments. AMRs, on the other hand, adapt to flexible production demands through dynamic path planning and autonomous obstacle avoidance.

Table of Contents

Navigation: What are the differences?

Vehicles Price

Deployment Cost

Safety

Flexibility

Scalability

Accuracy

Reliability

Maintenance

Total Cost of Ownership

Types of Vehicles

Main differences between AGVs and AMRs

Feature | AGV | AMR |

Navigation | Follow line requires simple sensor | Trackless navigation. All sensing is done |

Obstacle avoidance | NO, AGVs stop and wait until the | YES, AMRs goes around obstacles and |

Flexibility | It is more complex to add new routes or destinations. | Easy to remap and define new |

Vehicle cost | AGVs tends to be simpler thus less | AGVs tends to be simpler thus less |

Installation and | More complex, need more time and requires infrastructure cost (magnetic tape, wire, reflectors, etc) | Natural navigation is more sensitive to |

Safety | B56.5-2019 in US/ISO 3691-4:2023 | ANSI/RIA R15.08-1-2020 and R.15.08-2-2023 ISO 3691-4:2023 |

AGV Pricing:

AGVs are generally less expensive upfront due to their simpler technology and reliance on predefined infrastructure. However, the total cost can escalate with the need for route modifications and additional hardware.

AMR Pricing:

AMRs, equipped with advanced sensors and computing capabilities, typically have a higher initial cost. However, their flexibility and adaptability can lead to significant cost savings in the long run.

AGV Deployment:

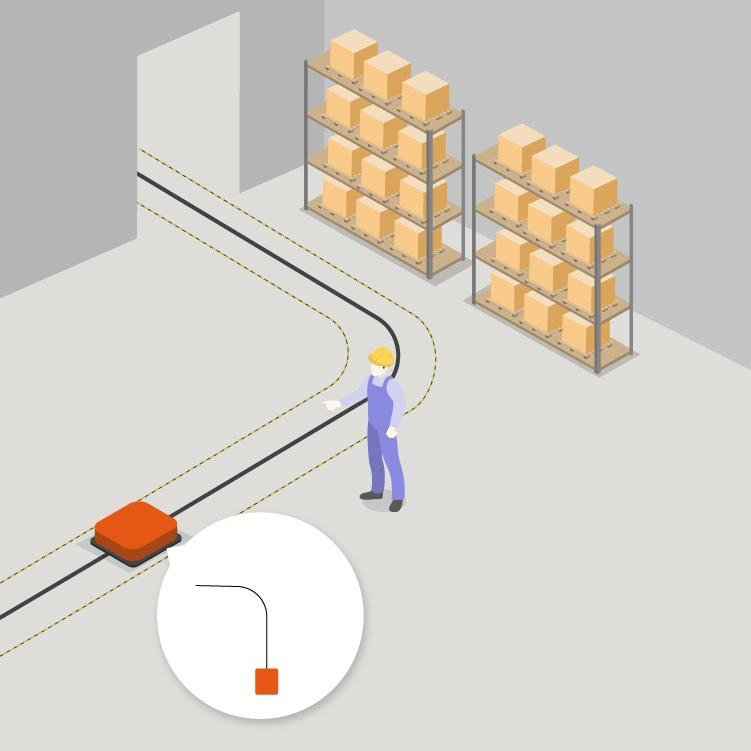

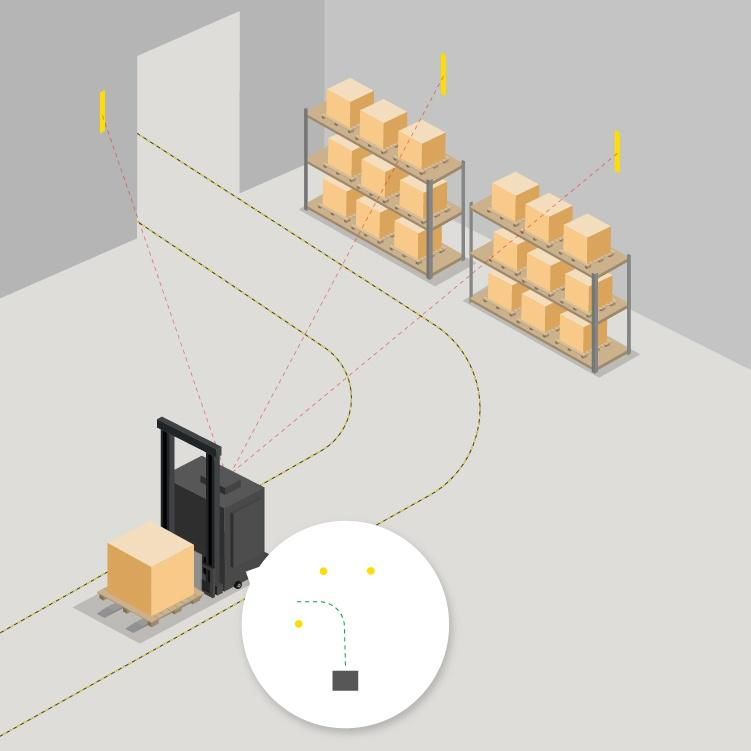

Deploying AGVs involves significant upfront costs for infrastructure setup, such as installing magnetic tapes or guide plates. This process can be time-consuming and disruptive to production.

AMR Deployment:

AMRs require minimal infrastructure changes, often only needing a mapped environment. This results in faster deployment times and lower costs, as well as reduced production downtime.

AGV Safety:

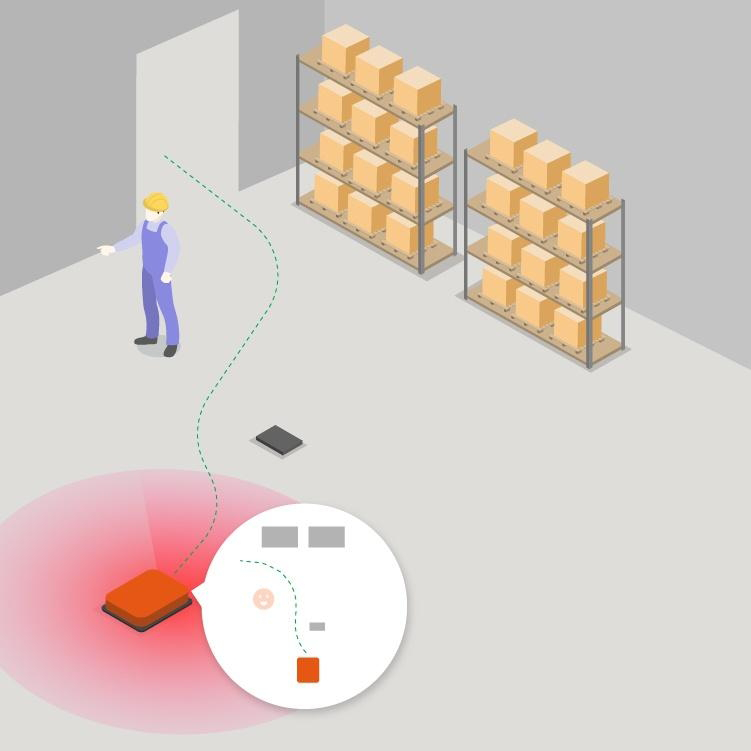

AGVs are equipped with basic safety features, such as obstacle detection sensors. However, their inability to dynamically reroute means they may stop in place when encountering obstacles, potentially causing delays.

AMR Safety:

AMRs feature advanced safety systems, including collision avoidance and dynamic path planning. They can autonomously navigate around obstacles, ensuring continuous operation and minimizing the risk of accidents.

AGV Flexibility:

AGVs are limited by their predefined routes, making them less adaptable to changes in the environment or production requirements.

AMR Flexibility:

AMRs offer high flexibility, capable of adapting to new layouts, tasks, and environments with minimal reconfiguration.

AGV Scalability:

Scaling AGV systems often requires significant infrastructure changes and additional costs, making it challenging to adapt to increasing demands.

AMR Scalability:

AMRs can be easily scaled by adding more units to the fleet, with minimal infrastructure modifications required.

AGV Accuracy:

AGVs offer high accuracy in following predefined paths, making them suitable for tasks requiring precise positioning.

AMR Accuracy:

AMRs provide comparable accuracy in navigation, with the added benefit of dynamic path adjustment to optimize efficiency.

AGV Reliability:

AGVs are reliable in stable environments with consistent tasks and layouts. However, they may struggle in dynamic or changing conditions.

AMR Reliability:

AMRs offer high reliability in various environments, thanks to their ability to adapt to changes and avoid obstacles.

AGV Maintenance:

AGVs require regular maintenance of their physical infrastructure, such as magnetic tapes or guide plates, which can be costly and time-consuming.

AMR Maintenance:

AMRs have lower maintenance requirements, primarily focusing on software updates and sensor calibration.

AGV TCO:

While AGVs have lower initial costs, their TCO can be higher due to the need for infrastructure modifications, maintenance, and potential downtime during route changes.

AMR TCO:

AMRs offer a lower TCO over time, thanks to their flexibility, scalability, and reduced maintenance requirements.

AGV Types:

AGVs come in various forms, including towing vehicles, forklift trucks, and unit load carriers, designed for specific tasks within fixed routes.

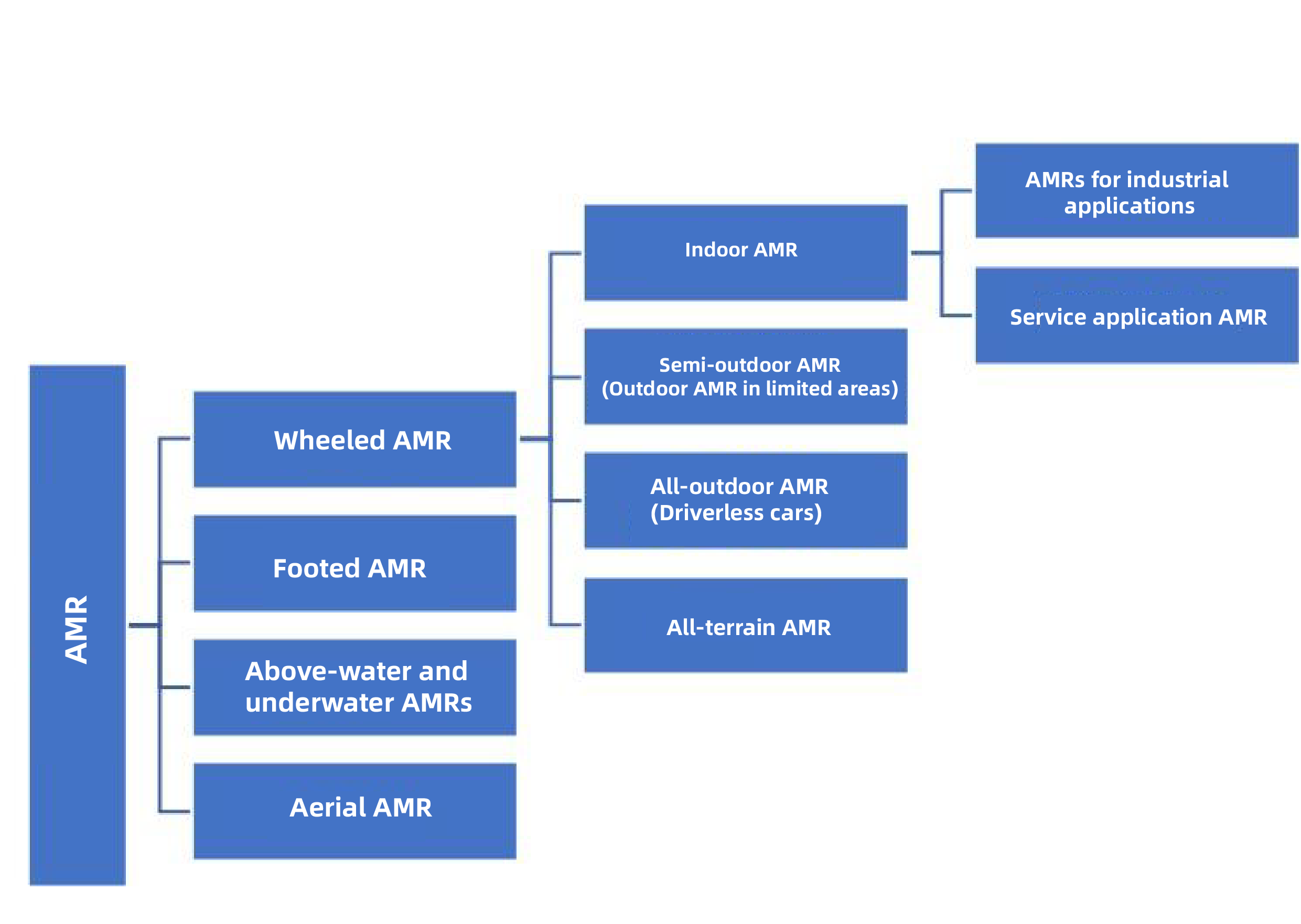

AMR Types:

AMRs offer a wider range of types, including logistics robots, service robots, and inspection robots, capable of adapting to diverse environments and tasks.

The competition between AGVs and AMRs is not a zero-sum game but rather a reflection of evolving industrial needs. AGVs excel in stable, repetitive environments with well-defined tasks, offering reliability and cost-effectiveness for such scenarios. AMRs, on the other hand, shine in dynamic, flexible settings where adaptability and efficiency are paramount.

As industries continue to evolve towards greater automation and flexibility, AMRs are poised to gain greater traction. However, AGVs will remain relevant in applications where their simplicity and cost-effectiveness align with specific operational requirements.

Ultimately, the choice between AGVs and AMRs depends on the unique needs of each business, including factors such as layout, task complexity, budget, and long-term growth plans. Both technologies have their place in the modern industrial landscape, and their coexistence underscores the importance of selecting the right tool for the right job.