AGV (Automated Guided Vehicles)structure analysis1.Hardware Structure Analysis

The hardware of an AGV consists of five core modules, each collaborating to achieve navigation, driving, material handling, and safety protection:

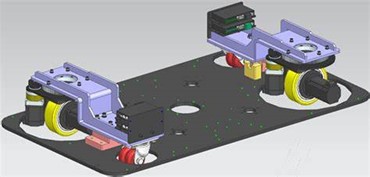

(1).Chassis and Frame

Function: Supports other components and provides structural stability.

Design Considerations:

l Utilizes high-strength alloys or carbon fiber materials to reduce weight and enhance durability.

l Optimizes center-of-gravity distribution for stability during high-speed operation or emergency stops.

l Case Example:

The chassis of a towing AGV must be compact to navigate narrow aisles (e.g., ≤1.2m wide

(2)Drive and Steering System

Key Components:

l Drive Motors: Typically brushless DC motors with power ratings from 0.5kW to 5kW to accommodate varying load requirements.

l Reducers: Reduce speed and increase torque for smooth operation.

l Steering Mechanisms:

Differential Steering: Achieves turns through speed differences between left and right motors, suitable for confined spaces.

Steerable Wheels: Independent steering wheels for tighter turning radii (e.g., ≤0.5m).

l Technical Specifications:

Maximum Speed: 1–2 m/s (adjustable based on application).

Gradeability: 5%–15% (higher for certain industrial scenarios).

(3)Navigation and Localization System

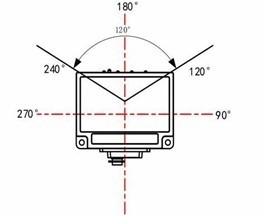

l Comparison of Navigation Technologies:

Navigation Method | Principle | Advantages | Disadvantages |

Magnetic Tape | Magnetic tape + sensor detection | Low cost, fixed paths | Low flexibility, complex path modification |

Laser Navigation | Laser scanner + reflector positioning | High accuracy (±5mm), high flexibility | High cost, reflector maintenance required |

Vision Navigation | Camera + SLAM algorithm | No infrastructure, strong environmental adaptability | High computational complexity, affected by lighting |

l Multi-Sensor Fusion:

High-end AGVs often integrate LiDAR, IMUs (Inertial Measurement Units), and vision sensors to enhance localization accuracy (e.g., ±2mm) and anti-interference capabilities.

(4)Power and Energy Management System

l Battery Types:

Lead-Acid Batteries: Low cost but short lifespan (300–500 cycles).

Lithium Batteries: High energy density (up to 200Wh/kg), long lifespan (1000–2000 cycles), becoming the mainstream choice.

l Charging Methods:

Manual Charging: Suitable for low-frequency use scenarios.

Automatic Charging: Enables 24/7 operation via contact charging stations or wireless charging technology.

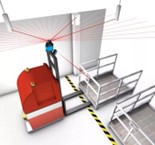

(5)Safety Protection System

l Sensor Configuration:

Laser Obstacle Detection Sensors: Detection range of 0.1–30m, response time <50ms.

Collision Bumpers: Mechanical protection that triggers immediate stops upon impact.

Emergency Stop Buttons: Ultimate safety measure for manual intervention.

l Safety Standards:

Compliance with ISO 3691-4 (Industrial Vehicle Safety Standards) to ensure safe human-robot collaboration.

(6)Material Handling and Actuation Mechanisms

l Common Types:

Roller Conveyor: Transfers materials via rollers, suitable for pallet handling.

Forklift Type: Similar to traditional forklifts, capable of lifting and retracting, with load capacities of 1–5 tons.

Robotic Arm Integration: Some AGVs integrate collaborative robots (e.g., UR arms) to perform complex tasks such as grasping and assembly.

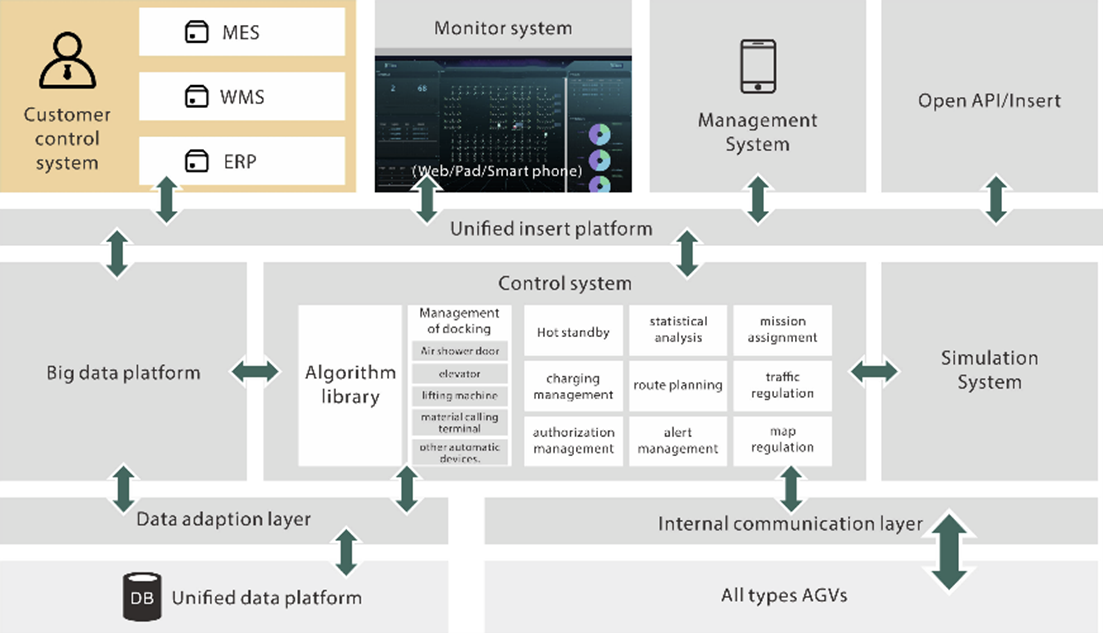

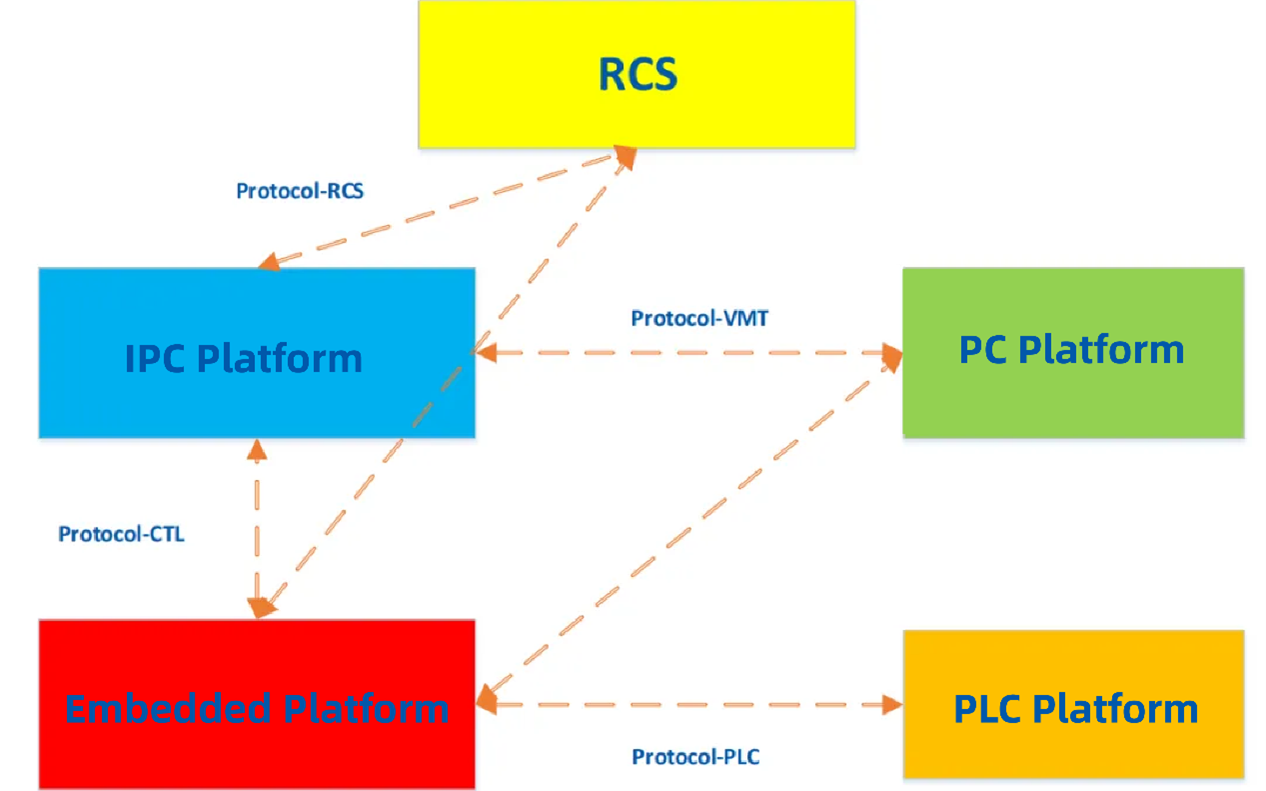

The software system of an AGV serves as its "brain," responsible for path planning, task scheduling, and real-time monitoring:

Control System

l Functions:

Receives commands from the upper-level system and parses tasks (e.g., transporting from point A to point B).

Invokes navigation algorithms to generate optimal paths.

Adjusts speed and steering in real-time to avoid obstacles.

l Technical Architecture:

Based on ROS (Robot Operating System) or proprietary real-time operating systems (e.g., VxWorks) to ensure low latency (<10ms).

Dispatch System

l Multi-Vehicle Collaboration:

Allocates task priorities via a central dispatch server to avoid path conflicts.

Example: In a 1000㎡ warehouse with 10 AGVs, the dispatch system ensures an average response time of <30 seconds.

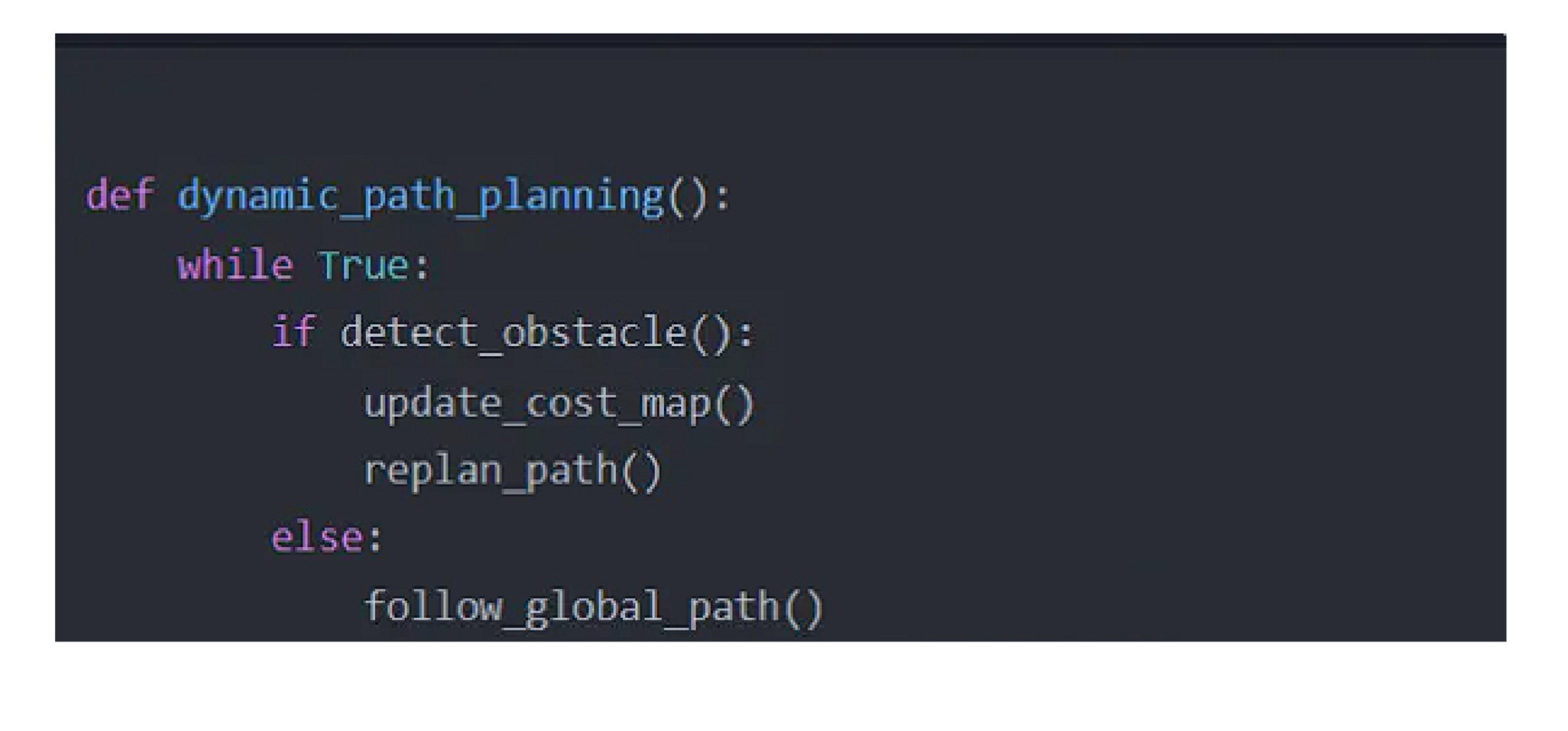

l Dynamic Path Planning:

Adjusts paths in real-time based on live traffic data (e.g., positions of other AGVs) to improve efficiency.

Human-Machine Interface (HMI)

l Functions:

Visualizes AGV status (position, battery level, task progress).

Allows manual input of task instructions or path modifications.

l Technical Implementation:

Web-based or mobile app interfaces supporting multi-user concurrent operations.

Typical AGV Structure Cases

Burden-Carrying AGV

l Structural Features:

Ultra-thin chassis (height ≤150mm) to slide under carts.

Load capacity of 500kg–2 tons, suitable for electronics manufacturing, automotive parts, etc.

l Navigation Method: Magnetic tape + laser-assisted localization for ±10mm accuracy.

Forklift AGV

l Structural Features:

ntegrates a mast, forks, and lifting mechanisms, with a load capacity of 1–5 tons.

Uses laser SLAM navigation to adapt to complex warehouse environments.

l Application Scenarios:Large logistics centers, heavy industry factories.

Composite AGV

l Structural Features:

Combines an AGV chassis with a collaborative robot (e.g., UR arm) to achieve integrated "transport + assembly."

Suitable for high-precision manufacturing in 3C electronics, semiconductors, etc.

AGV technology system

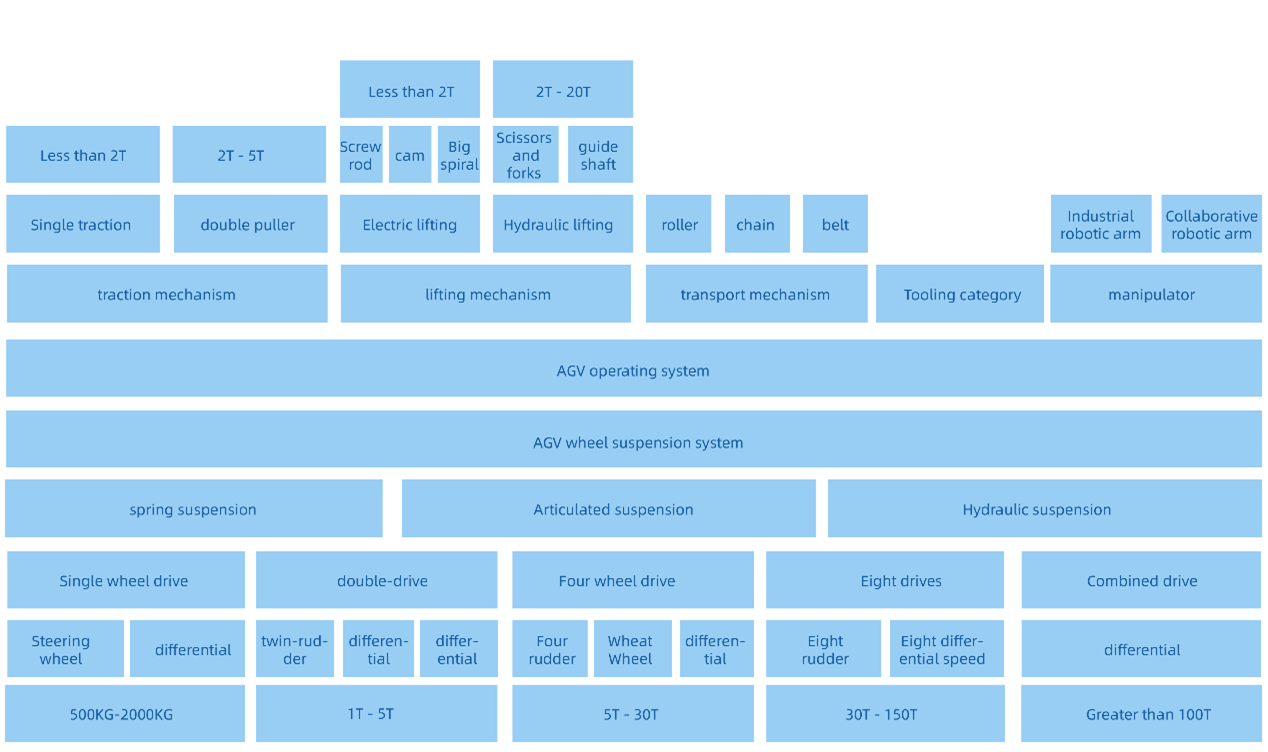

1. Panorama of AGV technology architecture: deep linkage of five core modules

AGV (Automated Guided Vehicle) is the "logistics bloodline" of the smart factory, and its technical system consists of five modules: mechanical, electrical, software, operation, and platform to form a close technical closed loop

l Mechanical skeleton: The golden combination of the wheel train × the suspension × the drive × the load

l Nerve veins: 20 types of sensors to build an environment-aware network

l Wisdom Brain: Dynamic scheduling algorithm digital twin rehearsal

l Perform hands and feet: More than 10 kinds of material transfer mechanism

l Data Hub: RCS protocol stack Factory MES deep coupling

2. Mechanical system: technological breakthroughs from millimeter-level accuracy to hundred-ton loads

2.1 Drive system: "Permutation and combination" of gear train design

l Basic wheel matrix:

Steering wheel: 360 ° omnidirectional movement (accuracy ± 1mm)

Differential wheel: Dual wheel differential steering (turning radius ≥ 0.8m)

McNam Wheel: Zero turning radius (suitable for scenarios below 5T)

2.2 Suspension System: The Art of Gaming between Load Capacity and Accuracy

Spring suspension:

%Stiffness calculation formula

k = (G*d^4)/(8*D^3*N)

%G: Material shear modulus | d: Wire diameter | D: Spring diameter | N: Effective number of turns

Typical application: Linde L14 electric forklift (maximum load 2T)

Hydraulic active suspension:

Pressure closed-loop control accuracy: ± 0.05MPa

Application case: Hangcha 30T heavy-duty AGV (ground roughness compensation ± 15 °)

2.3 Special agencies: material interaction beyond imagination

3D docking system:

Laser ranging accuracy: ± 0.1mm (Keyence IL-300 sensor)

Six dimensional force sensor feedback: XYZ axis force control ± 2N

Hydraulic scissor lift:

Maximum travel distance: 3.2m (Yufeng EPQ20 model)

Speed control: 0.1m/s~0.5m/s continuously variable transmission

3 Intelligent Control System: The 'Neural Center' of Industry 4.0 Era

3.1 Sensor Networks: The "Eighteen Martial Arts" of Environmental Perception

Navigation sensor matrix:

⊙ Magnetic navigation: Magnetic stripe spacing detection accuracy ± 1cm (SAT MS1000 sensor)

Laser SLAM: angular resolution of 0.1 ° (SICK TiM781)

Visual guidance: 2-megapixel industrial camera+deep learning recognition

Three Swordsmen for Safety Protection:

Laser obstacle avoidance: 4-layer protective area (SICK microScan3)

Emergency stop circuit: SIL3 level safety certification (Schneider XPS series)

⊙ Tilt angle detection: ± 0.1 ° accuracy (Xingyu Technology SX-01)

3.2 Motion Control: The Secret to Achieving Millimeter Precision

[Speed loop] PID parameters: Kp=2.5, Ki=0.03, Kd=0.01

[Position Loop] Fuzzy Adaptive Algorithm (Response Time<50ms)

Typical fault handling:

Motor overheating: temperature rise>75 ℃ triggers load reduction protection

Encoder exception: CAN bus check+redundancy check

4、 Intelligent scheduling system: the 'strongest brain' of factory logistics

4.1 Dynamic scheduling algorithm

l Core algorithm library:

l Multi AGV collision avoidance strategy:

Time window method: ± 0.1s synchronization accuracy

Potential field method: repulsion coefficient β=0.8

4.2 Digital Twin System

l Factory simulation accuracy:

Beat simulation error:<3%

Prediction of AGV quantity: supports 200+collaborative simulations

l Typical application scenarios:

A certain automobile welding workshop: reduced 12% of empty driving distance through simulation optimization

3C Electronics Factory: 18% reduction in cycle time

Industry Implementation Case: The Technological Revolution Behind Digitalization

1.Automotive Manufacturing: Full Process AGV Matrix

l Case study of a German car company:

57 AGVs form a flexible production line

Single day transportation mileage: 3826km (equivalent to Beijing to Lhasa)

Positioning accuracy: ± 1mm (visual+laser composite navigation)

2. Intelligent Warehousing: Kiva System Upgraded Version

l Data from a certain e-commerce warehouse:

500 AGV cluster scheduling

Picking efficiency: 1200 pieces/hour/unit

Charging strategy: 20% battery threshold+dynamic charging queue